Sustainability is possibly a word that is used so frequently in everyday life, that sometimes we lose sight of what it actually means!

At Cepac, sustainability is at the heart of everything we do, from the raw materials we use to make our packaging solutions, through to the way we generate and utilise energy for our equipment and factories.

We don’t just use it as a buzz word, we practice it in every aspect of our daily business life, covering Scope 1 and Scope 2 directives, and implementation of Scope 3 over the coming months and years.

Ultimately, consumers are more aware about the impact we are having on the environment and they are starting to make informed decisions about their buying habits, citing sustainability as being one of the most important drivers for them. That includes the way in which products are packed and shipped. That is why we help brand owners and packaging buyers develop superior corrugated packaging solutions.

Let’s look at the various ways with embrace sustainability within our business.

Solar power: thanks to ongoing investment in state-of-the-art solar panels, we are utilising the sun’s rays to help us generate energy as well as to heat water within our Headquarters in Rotherham. Green energy is a high priority to Cepac, and we are committed to rolling out additional solar panels at other sites within the Group over the coming months and years.

Energy usage: one of Cepac’s USPs is the quality of its production machinery. We always have a keen eye on technical specifications when we are looking at adding new equipment to our factories around the UK and as machinery designs evolve all the time, we partner with some of the industry’s leading machine designers and manufacturers to ensure our chosen equipment is cost efficient to run, keeping our energy usage as low as possible. For us, new machinery has to offer low cost of operation, making this a key area of investment focus moving forward.

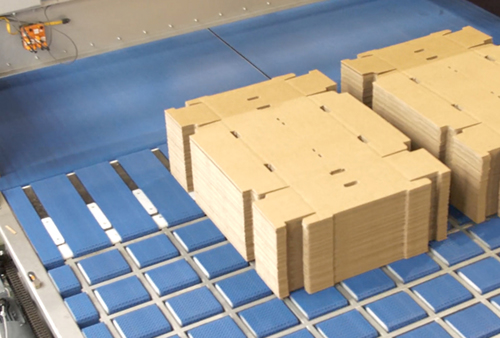

Automation of equipment: we employ some of the best corrugated packaging machinery operators in the UK and our emphasis is to ensure they can get the most out of the machinery they run! To achieve this, we invest in what is referred to as ‘materials handling systems’ – these are machine units that move stacks of board around the factory, deliver them to each machine line and feed the sheets of cardboard into each machine, removing the need for heavy, manual lifting. The Health & Safety of our operators is one of our guiding principles, and of course, these often-automated handling systems also help reduce the number of fork-lift truck movements in the site, which is good for everyone in our factories.

Reducing raw material waste: with the latest production machinery, we often specify camera-based inspection systems to ensure we don’t waste sheets of cardboard during the production process. These cameras and their associated AI software allow for a reduction in waste, ejecting any sheets that are defective – and of course, this means that only perfect boxes are delivered to our customers, allowing their case erectors to run at optimum speeds.

Use of world-class papers: thanks to almost three decades of experience in the industry, Cepac is well positioned for sourcing and specifying some of the best papers available from the market to make into corrugated board. Here, we keep a close eye on industry trends for lighter, stronger papers made from recycled content. Did you know that in 2021, the European paper industry value chain pledged to recycle 76% of all paper consumed by 2030, or a 76% ‘recycling rate’? The recycling rate is defined as the ratio between the recycling of used paper and board, including the net trade of paper for recycling and the consumption of new paper and board. Of course, all our papers are sustainably sourced through FSC Certification, meaning we know the origin of each and every paper reel we use to make into cardboard . For us, recyclability of the finished box allows the consumer to easily and safely recycle their packaging after use, going back into the production cycle to be turned back into paper again. Or if chosen, paper can be easily composted at home or collected for Industrial composting purposes.

All of these cover our Scope 1 and 2 directives, both upstream and downstream. Scope 3, which continues to evolve for Cepac, covers aspects of what our suppliers are doing.

Logistics is a primary area: we are working with our chosen logistics company, who are already rolling out their own investment in implementing the use of a next generation HVO biodiesel as an alternative fuel and this is something that, when taken into context with each step in our supply chain, helps us to showcase our move to a greener future.

For more information, see our sustainability page: