Twenty five years of achievement; a quarter century anniversary is important to any company.

For Cepac, one of the key factors in our success is the dedicated and well trained workforce, from the shop-floor right through to the board room. Many of the team have grown with the business over the course of the past two and a half decades. There is great pride in the product and a constant emphasis upon measurement and control throughout the process.

We are celebrating this milestone, with the utmost thanks to each and every member of the team over the last 25 years.

Read on, as we highlight a few key company events—

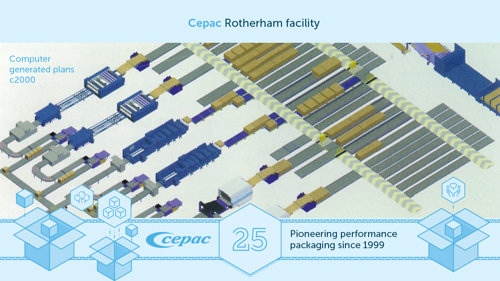

In November 1999, Cepac’s greenfield plant in Rotherham came on stream, combining a number of industry firsts.

At the heart of our greenfield site was the first wide width, 2.8m corrugator in the UK with ‘bandleader’ pressure belt system from BHS Corrugated. We were also the first box plant with vacuum transfer on all converting machines, allowing us to stand ahead of the crowd with the introduction of Performance Packaging.

We made a big impact on the UK corrugated packaging industry landscape – so much so, a leading industry journal later wrote an article with the headline “New kids on the block” – the mission was to live up to the hype!

In 2003, Cepac commissioned a Göpfert Maschinen GmbH Evolution rotary die-cutter.

At the time, it was one of the first of its kind in the UK, meaning we could produce packaging with the highest level of print quality, all die-cut in one process. Since then, we have picked up many print-related awards for packaging produced on this great machine.

Investment in state-of-the-art machinery has been a priority for Cepac since day one. For twenty five years, Cepac has invested in best in class machinery and highly skilled operators to keep us ahead of the field.

Rotherham facility

Our Rotherham facility was custom built and fully automated with state-of-the-art casemakers and large format rotary die cutters. The combination of kiss touch printing, vacuum transfer and pressure sensor technology underpinned our development of Performance Packaging.

From the outset Cepac has set the benchmark for quality, service and productivity and was the first box plant in the UK to obtain the BRC Global Standard for Food Safety and FSC chain-of-custody.

In early 2008, we undertook a sizeable building extension at our Rotherham facility. This was put in place to house a new Bobst Quatro double die-cutting line.

Cepac had already established the record as the most productive box plant in the UK and their factory extension in 2008 took the industry by surprise. This was the launching pad for further groundbreaking technology, not only with the Bobst Quarto with Double Die technology but also a quantum jump in additional capacity.

2013 Corporate aquisitions

With a market realignment from some of the larger integrated companies in 2013, we spotted an opportunity to acquire three successful businesses, allowing us to grow our footprint within the UK.

The three plants Cepac acquired were:

• Darlington, where we focussed on the production of innovative, sustainable packaging

• Rawcliffe, a centre of excellence for high quality, specialist packaging

• Doncaster, one of the UK’s leading manufacturing sites for POS displays.

Our vision to create sites with a particular market focus has proven time and again to be the right choice, most notably with the recent POPAI Award win for a POS display produced for Pernod Ricard.

The performance of these operations has exceeded all expectations.

2016 Digital print at Doncaster

As part of our investment plans for the latest print technologies, we installed an HP Scitex 17000 digital press at our Doncaster facility in 2016. The addition of this digital print technology meant we could increase not only the complexity of print on displays, but it meant we could also do individual prints or messaging on each and every sheet printed, opening up a whole realm of opportunities for our customers!

In 2017 two building extensions were completed in Rawcliffe and Doncaster; the site at Doncaster almost doubled in size, and the extension at Rawcliffe meant we could significantly expand production.

To this day, Cepac offers the advantages of Digital, Pre-print and ultra-high quality Flexo post print, combined with a range of muti-point gluing and finishing services.

Customer requirements are changing and there is growing demand for ultra high-quality print combined with an exceptionally fast speed of response.

This page will be updated over the next twelve months with milestones and mentions from our history.

What our people say

→ https://www.cepac.co.uk/news/staff-focus-roundup/

Cepac, Pioneering performance packaging since 1999.